Mechanical advantage is a measure of the force amplification achieved by using a tool mechanical device or machine system. We offer you the optimum.

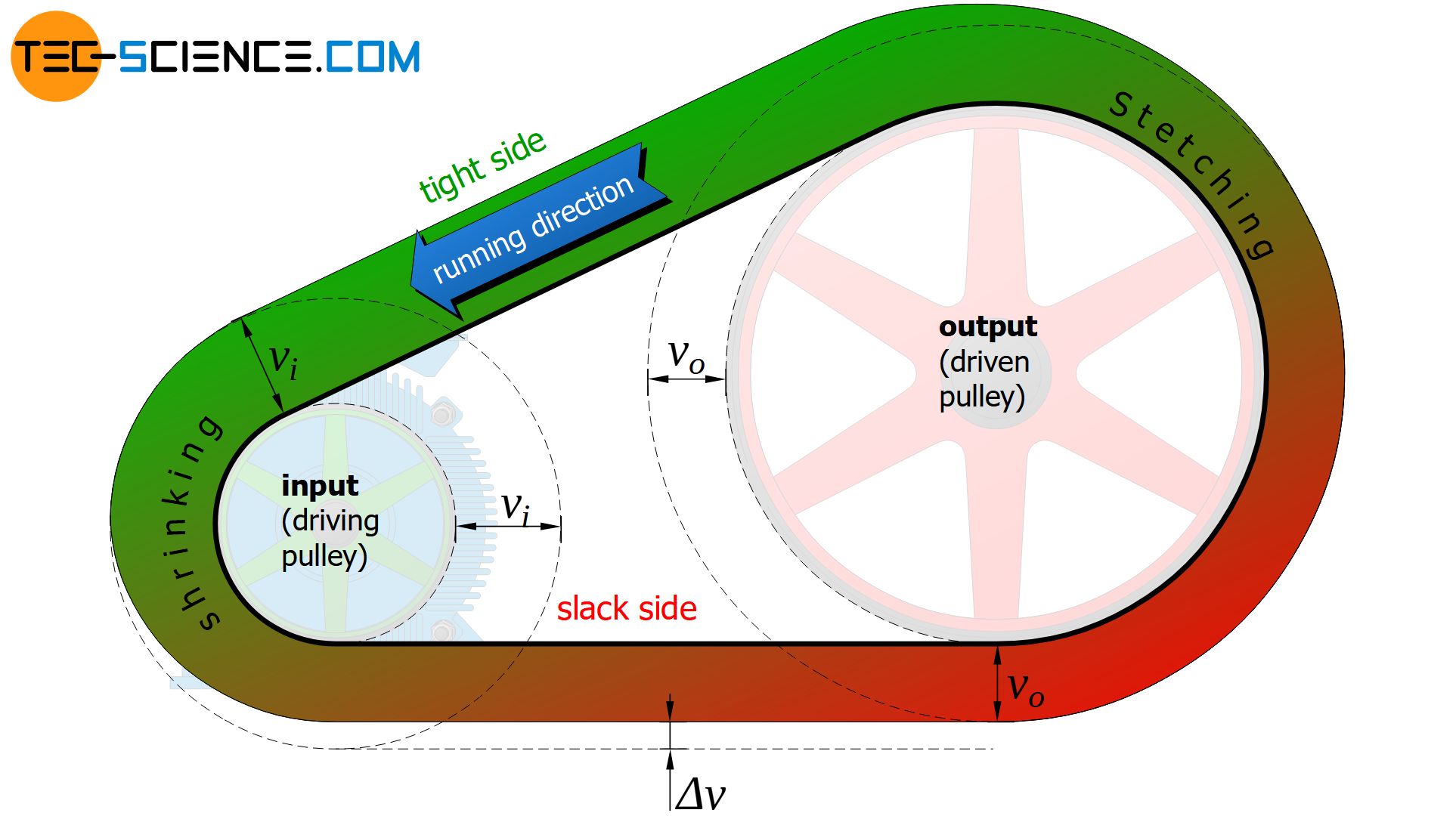

Slippage Of The Belt In Belt Drives Tec Science

Design consideration of this paper is to calculate Mixing Force Mixing Value belt tension and required power by mixer.

. SNS JIS V Pulley A. Dry friction is a force that opposes the relative lateral motion of two solid surfaces in contact. To meet all the expectations of the market Hutchinson has expanded its product portfolio with a range of Hutchinson V-belts timing belts and pulleys.

Nominal diameter ø67 to 710 with 1 to 3 runners available in wide selection good balance measurements and directly usable on high speed rotator. Can be freely. The result obtained show the Mixing force of 14715 N mixing volume of 0348 m 3 and required power by mixture of 243 hp.

The model for this is the law of the lever. Machine components designed to manage forces and movement in this way are called. Hutchinson develops and manufactures complete power transmission system incorporating ribbed belts for HVAC Conveying industrial motors agriculture and energy supply markets.

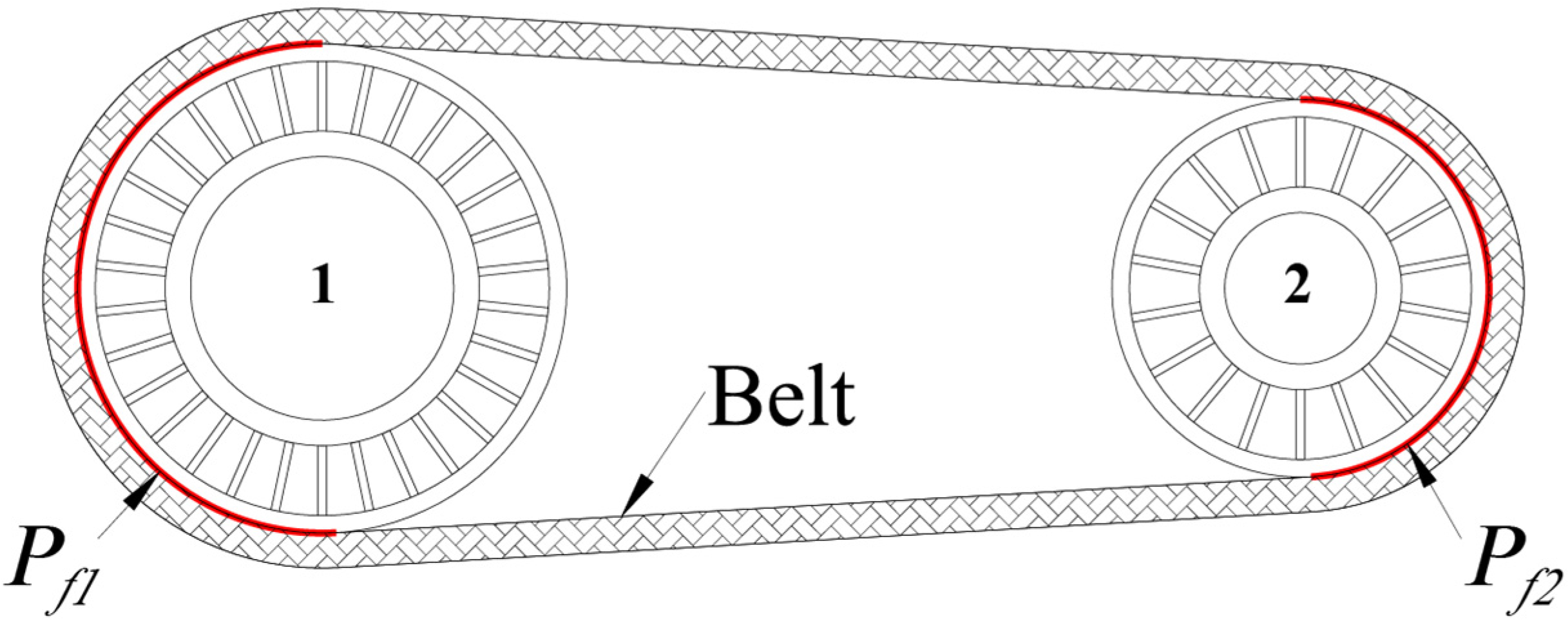

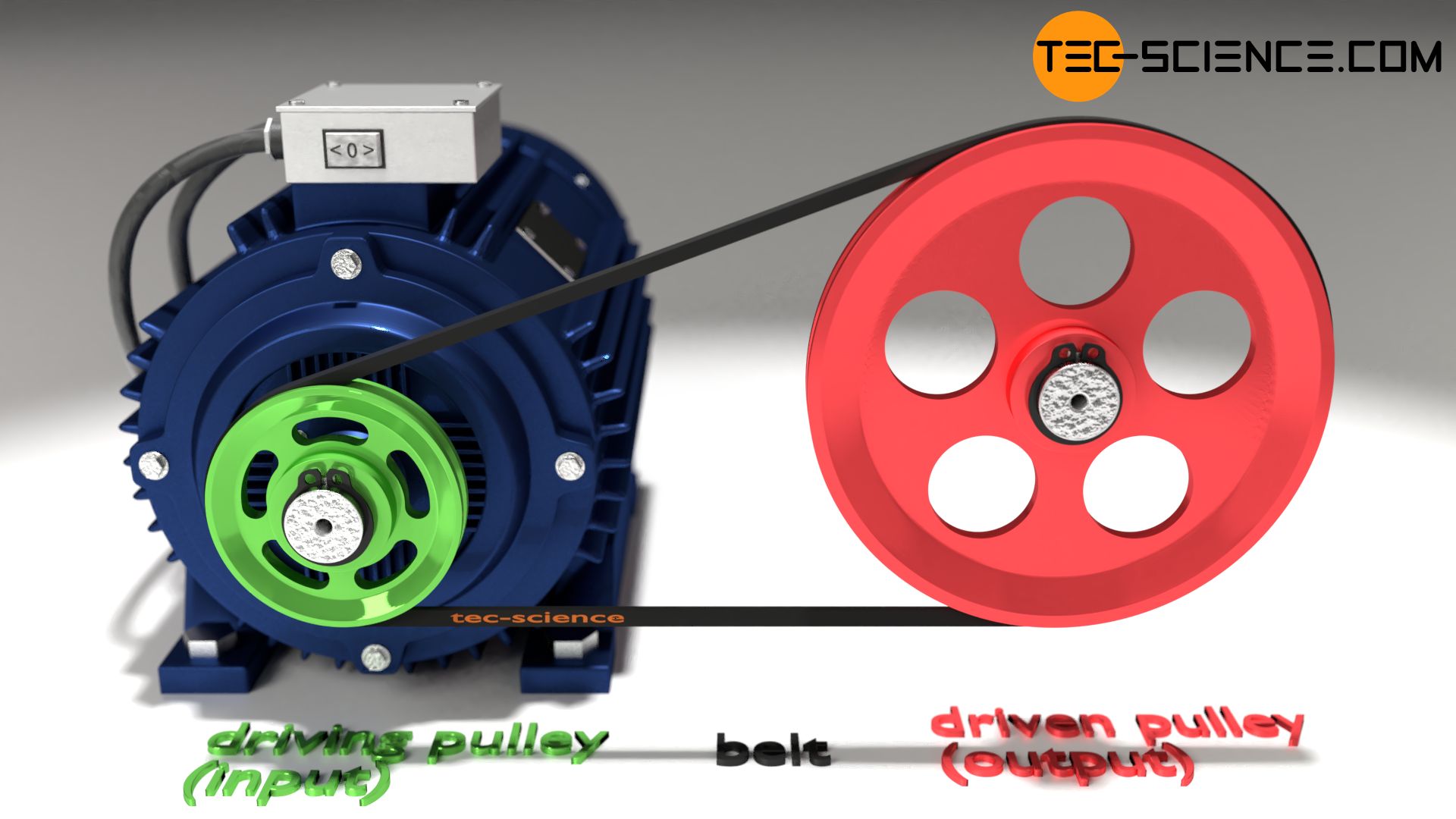

Belt drive power transmission. There are several types of friction. Our Application Technology experts offer you free support service regarding the application of our products and also help solve your drive problems.

Pulleys with equal. Dry friction is subdivided into static friction stiction between non-moving surfaces and kinetic friction between moving. Features SNS JIS V pulley is a new addition to the mechanical series with 360 types standardized rotation ratio distance between shafts etc.

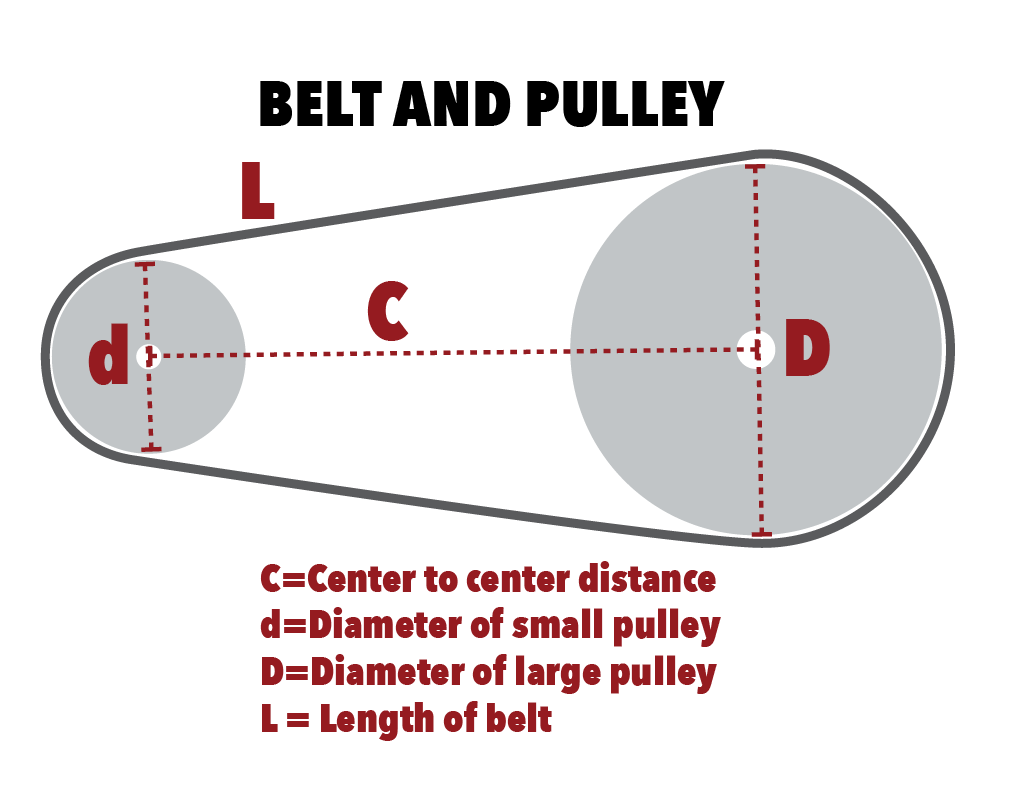

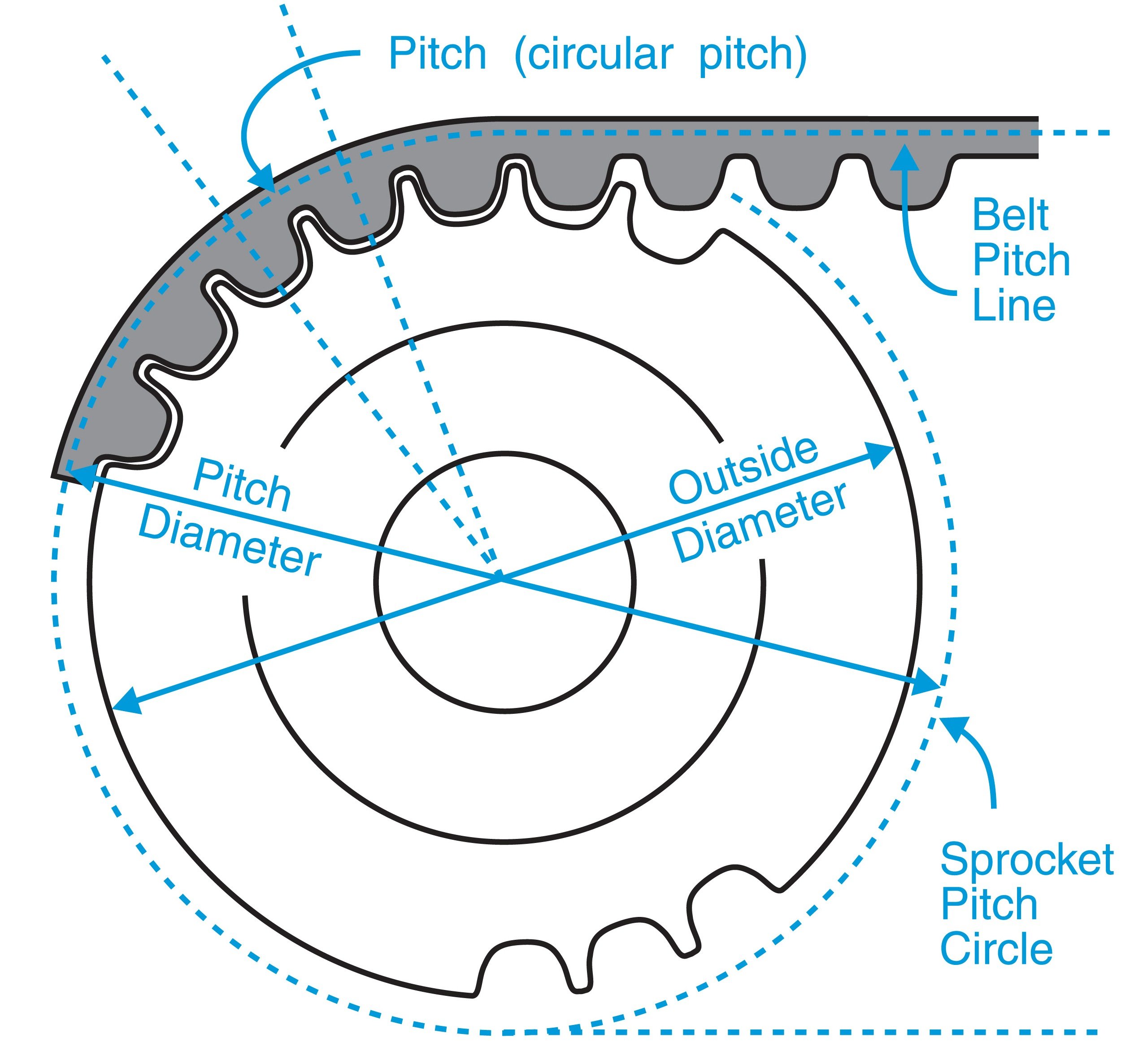

Power of 3 HP. The device trades off input forces against movement to obtain a desired amplification in the output force. In contrast the formerly used pitch length calculation was based on the sheaves pitch diameter.

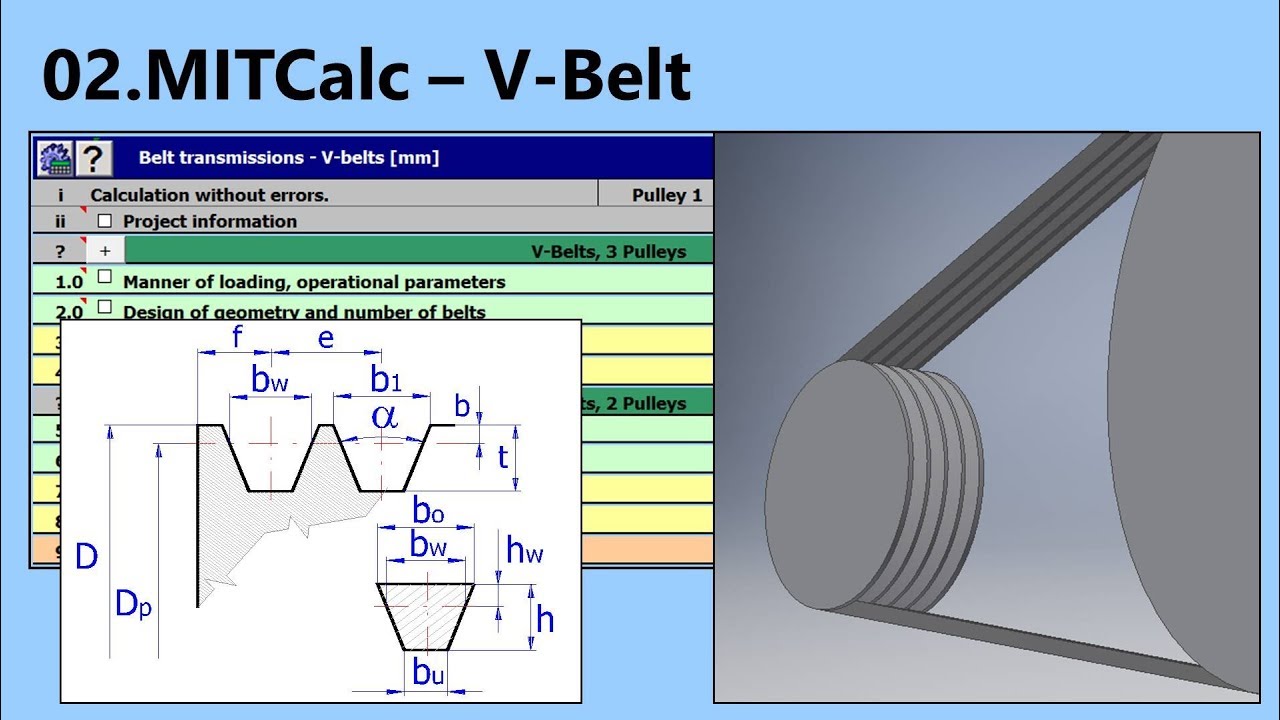

Especially regarding large volumes you should make use of this service. How to calculate datum length. Methods for the design and calculation of drives with Optibelt V-belts and V-grooved pulleys for industrial applications.

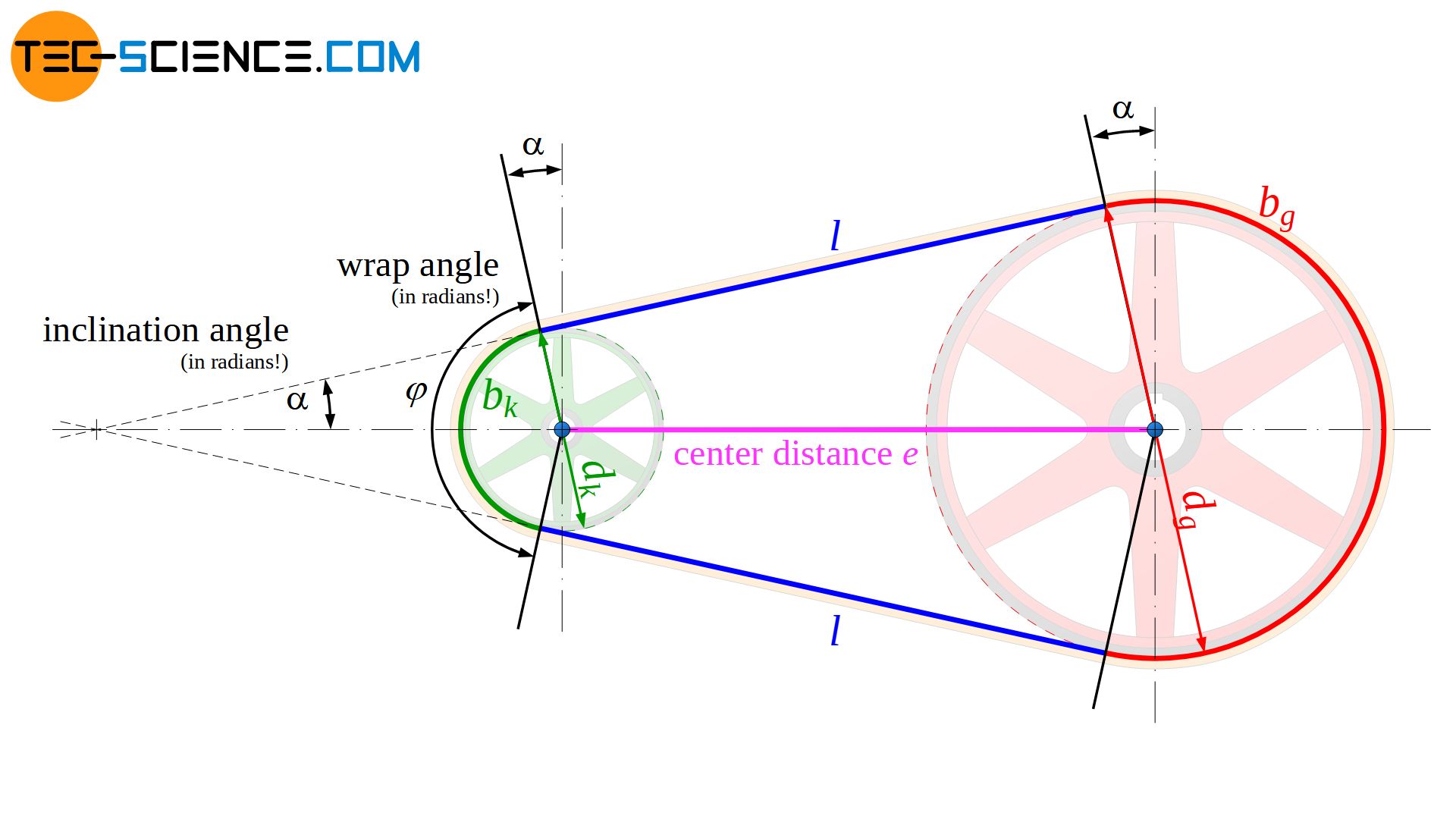

For smaller jobs the concrete made at the. Friction is the force resisting the relative motion of solid surfaces fluid layers and material elements sliding against each other. This is important when calculating the length of a belt because the datum length which is the norm for standard V-belt measurements today is based on the datum diameter of the sheave.

6 7 Belt Friction Engineering Libretexts

Applied Sciences Free Full Text Numerical Design Method For Cvt Supported In Standard Variable Speed Rubber V Belts Html

Solidworks Tutorial 53 Design And Motion Analysis Of V Belt And Pulley Assembly With Tensioner Youtube

V Belt Calculation And Design Mitcalc 02 Youtube

Calculating Power Transmitted Using Flat Belts And Vee Belts Youtube

Step Cone Pulley Design Optimization Design Optimization

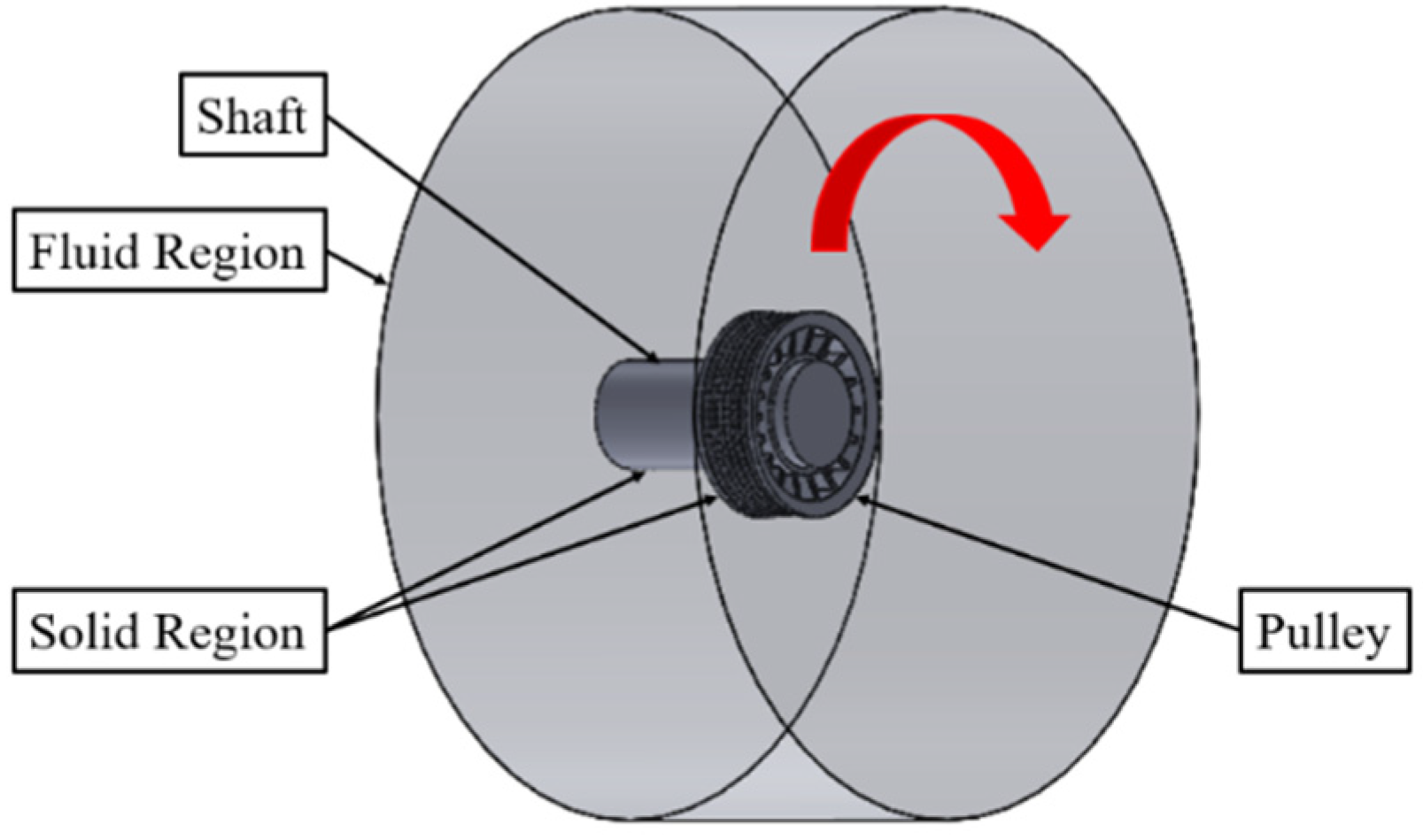

Applied Sciences Free Full Text Analytical Numerical Model For Temperature Prediction Of A Serpentine Belt Drive System Html

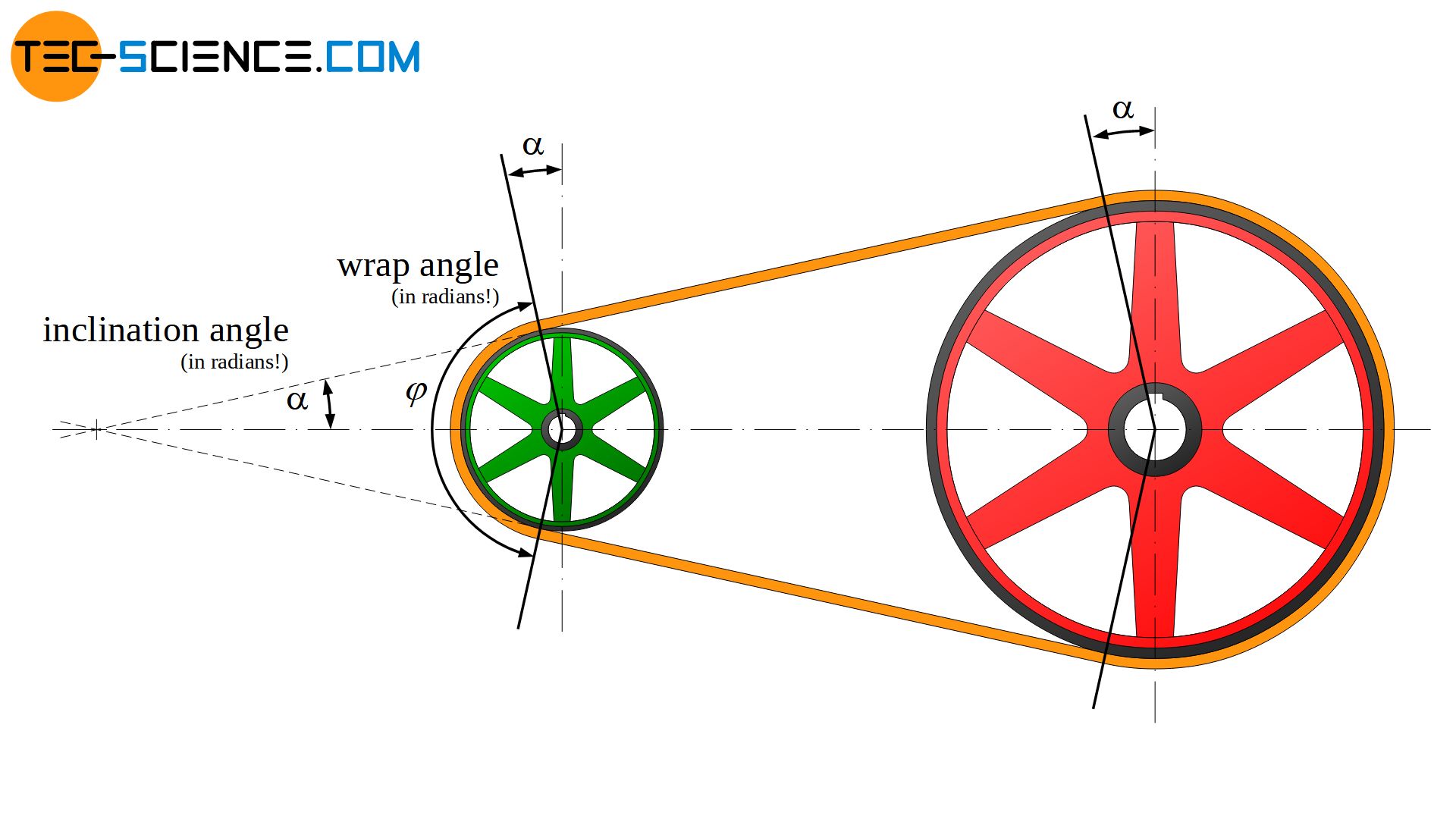

Calculation Of The Belt Length For Belt Drives Tec Science

Applied Sciences Free Full Text Analytical Numerical Model For Temperature Prediction Of A Serpentine Belt Drive System Html

Designing A V Belt Drive For Power Transmission Choosing A Standard Belt Length Center Distance Youtube

Finding The Length Of A Belt Using Radians And Simple Geometry Youtube

Calculation Of The Belt Length For Belt Drives Tec Science

How Does A Belt Drive Work Tec Science

Belt Length And Distance Between Pulleys Calculator Sudenga Industries

Pulley Belt Calculations Belt Length Distance Between Pulley Wheels Youtube

Excel Tips Calculation Of Geometric Figures Volumes Areas Geometric Excel Graphing

How To Find Belt Drive Pulley Rpm And Diameter By Calculation Rotating Static Equipments Youtube

0 comments

Post a Comment